I have a new update for you on Millie’s Remodel. Join me as I uncover the damaged wood floors and ask the question: Can We Save these Wood Floors?

Millie’s Remodel: Can We Save These Wood Floors?

I know it’s been a minute since you got the last update, but unfortunately, my husband contracted COVID and it was the scariest two weeks of my life while I tried to prevent the boys and I from getting sick. While I cared for my husband and worried about his health, I documented his symptoms and what it was like caring for someone with COVID in my Instagram highlights. Unfortunately, I didn’t start saving the stories until a few days in. Regardless, it should give you a good idea what it was like caring for someone who has COVID and how his symptoms progressed.

Can We Save These Wood Floors:

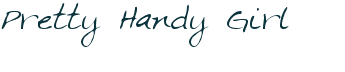

Now back to Millie’s Remodel, the real star of this show. When I purchased the house, it had brand new brown berber carpeting in every room except the kitchen.

Crazy enough, the carpet wasn’t professionally installed, it was cut and the shoe molding was tacked on top of it. Which made it super easy to remove and allowed me to see that there were wood floors underneath before I bought the house.

Although I saw some of the floor before closing, I had no idea what type of shape they were in. What lurked underneath the carpet were real wood floors in REAL BAD SHAPE.

Lots of stains and even a nail polish spill (not blood!)

A spot in front of the bathroom had the worst damage, but my floor refinisher felt confident it would sand out.

This bedroom had the least damage, but this room had a horrible smoky/fishy odor. We think the previous tenant was a cigarillo smoker based on all the plastic tips I found in the backyard.

Patching the Wood Flooring:

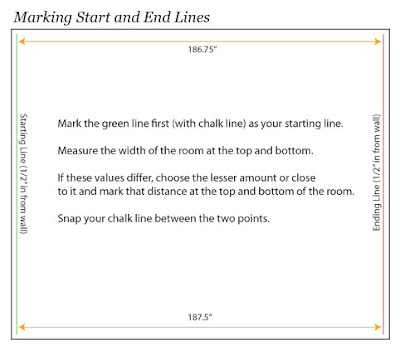

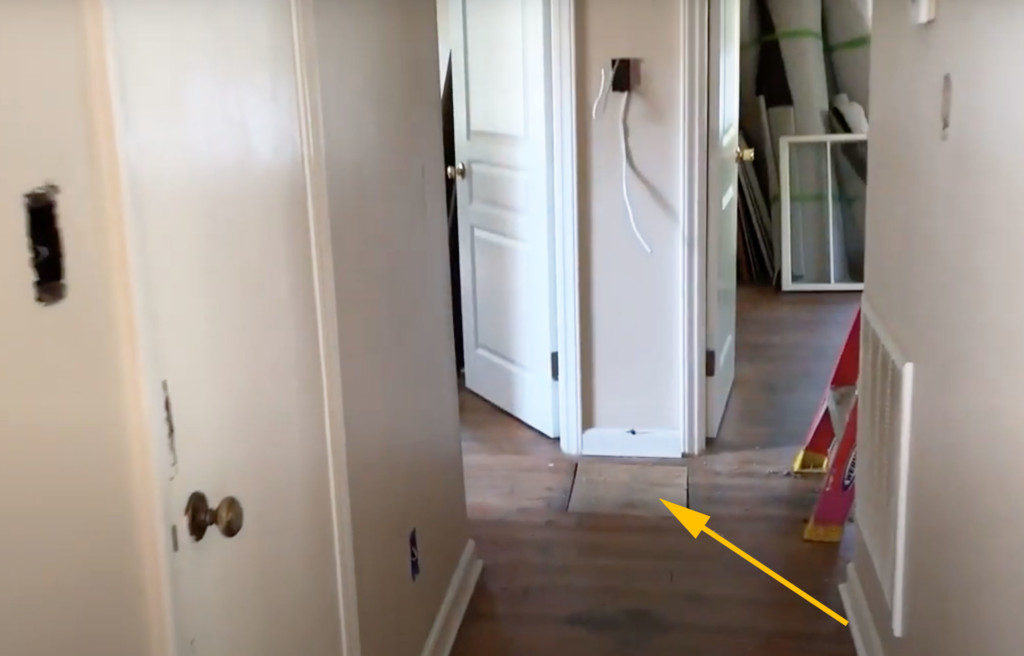

Before the floors were scheduled to be sanded, my wood floor contractor sent out his “guy” to patch the plywood in the hallway and the area where I removed a doorway to open up the living room more.

Here’s where that plywood was in the hallway.

He was able to match the oak flooring and feather in some replacement boards.

And then the floor refinishing came to a screeching halt. This was one of the most frustrating contractors I’ve ever dealt with! (I won’t share the name of the refinisher I worked with. But, I will NEVER work with him again! If you live in the Raleigh/Durham area and want to know who I recommend and who to steer clear of, just shoot me an email.)

Rant Warning:

The flooring contractor promised that his guy would come to sand the floors in the evening after I left. This should have been the first red flag, as most reputable companies send their employees during the day. But, I was just happy to have my job scheduled for refinishing.

Every morning I’d show up at the house expecting to see progress made on the floors only to be let down when I realized nothing had changed. I’d text the refinisher and he’d ultimately get back to me after several hours or sometimes a day later (again, another red flag.)

This back and forth of texts and promises went on for two weeks! For 10 days I would show up and find nothing done. But, the biggest issue was all the time I spent stashing everything into the bathrooms and then emptying them in the morning so I could continue tiling in there.

This might seem like a minor inconvenience, but I spent 20 minutes out of my day each day loading and unloading tools and tiles. Add that up over 10 days and that was over 3 hours of time I wasted loading and unloading all my equipment.

Finally, I told the flooring contractor I was headed out of town for a few days and I needed the floors to get done while I was gone. I was fed up.

Making the Stain Decision:

Finally, the floors were sanded while I was away. The floor refinisher sent me a picture of the floors after sanding and offered me a few stain colors to choose from. What a kind thing for him to do, right?

Umm, yes, except he didn’t tell me what the stain colors were! I can’t even properly express my frustration. He sent me the photo above with no stain color names. I was able to figure them out by zooming into the picture (except the “mystery stain” color.) He never got back to me with colors. For your convenience here is what I was able to decipher:

How I Choose Stain and Paint Colors:

I’m very methodical when I choose paint or stain colors. Usually, I look at the colors in the space for at least a week. But, in this case, I needed to make a decision quickly. Luckily I have a friend who had recently used Golden Oak and told me to search for pictures of it online. It seemed like the perfect mid-range stain that would go well with the mid-century vibe I was using in Millie’s Remodel. Although I liked the weathered gray, it was too gray for this house. And provincial was darker than I wanted the floors to be. Finally, I texted my flooring contractor and told him to go with golden oak. I said a little prayer that they would be finished when I got back to Raleigh.

Wood Floor Stains:

When I got back, the floors had finally been stained! Hooray, but also not good. Most of the house looked pretty good. There were some mild stains still showing, but I was okay with that. In my mind, it’s okay when a 63-year-old house has some signs of age.

I never expected perfection, but in several areas, there were very dark stains. I was starting to doubt that the wood floors could be saved.

There was a huge water stain outside the bathroom. And another bad stain near the front door.

I was disappointed the floor refinisher didn’t call me to suggest we go with a darker stain. I tried to call him and ended up hearing back the next day. He said his guy would come to patch the really bad spots. This was a great solution and luckily he was able to come back within a few days to patch the floor where the bad stains were.

The spot near the bathroom needed the most patching.

Never Pay a Contractor Until the Job is Complete:

This is the point where suddenly my floor contractor was super communicative! I got multiple texts saying he wanted to come by and pick up a check to pay his guy. I told him not until the job was complete. He was so persistent, but luckily I didn’t give in.

For days he hounded me for payment. This is a huge red flag! A contractor who can’t pay their “guys” because they rely on the income from one job to the next is not managing their business well.

Luckily, my stubbornness paid off, and the floors were finished quickly so he could get paid.

Could These Wood Floors Be Saved?

The answer is a resounding YES! Feast your eyes on these beautiful original 1957 wood floors refinished with Minwax Golden Oak.

They certainly aren’t perfect, but that’s okay, this house deserves to show her age a little.

Remember the living room before? Can you even believe this is the same floor?

And remarkably the back bedroom never smelled so fresh!

Remember this was the before:

The other bedrooms came out phenomenal too. What do you think of the door colors I chose? It’s Dark Night by Sherwin Williams.

The walls are Repose Gray by Sherwin Williams and I love how simple and neutral the color is.

Unlike the Saving Etta house, all the rooms are painted the same color. This makes it easier for me to repaint when renters move out.

I’ll leave you with the transition from the hall to the kitchen tiles. I used a Schluter Reno-V profile to bridge the transition. You can read my entire article and see the video for 11 Tips to Get Professional Looking Tile Floors!

How to Hire Great Contractors:

I’ll be the first to admit, I could have followed my own advice when hiring this flooring contractor. I should have asked for references and followed up more. Instead, I rushed to hire him because his price was good (red flag number 4.) But, I did follow my own advice and didn’t pay him until the work was done. This one thing saved me the headache of trying to get him back to finish the job.

Read my article on how to hire great contractors and questions you should be asking?

Have you ever had bad experience with a contractor? Do tell! I’m also curious about what you think about the stain color I chose.