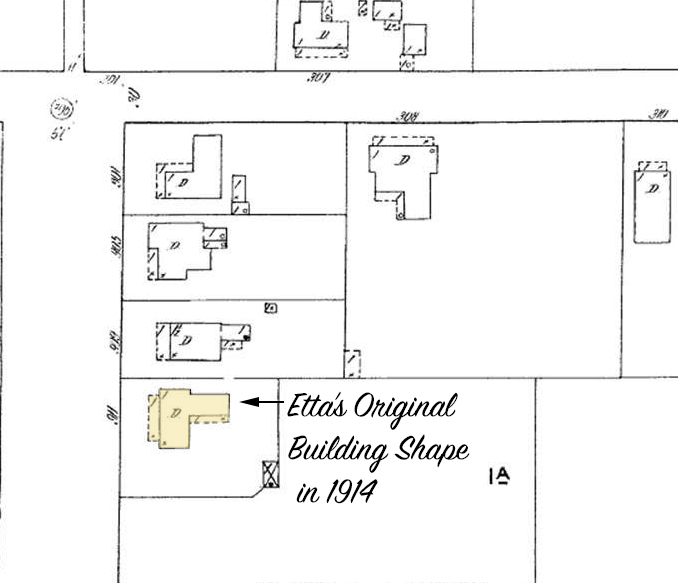

Saving Etta: Exterior Progress Update

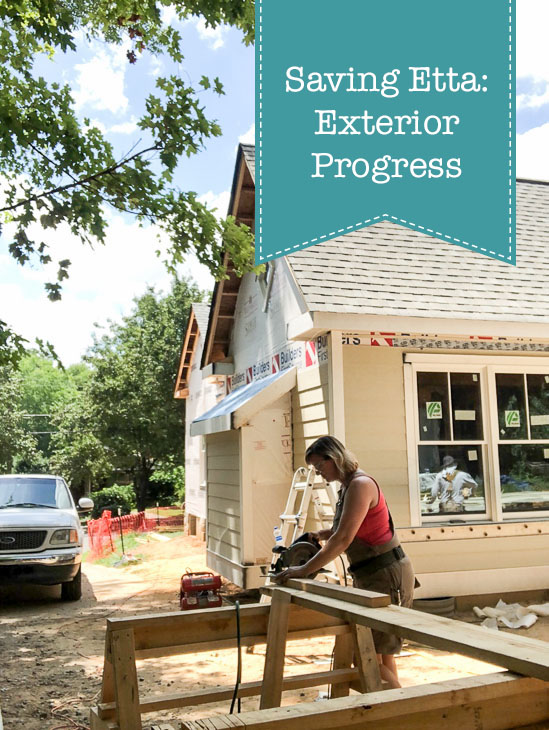

Things moved quickly on the Saving Etta Project after the framing was completed. It was a mad rush to get the house dried in. All the rain we had while digging the foundation continued after the framing was complete. Although the roof and synthetic underlayment helped, I still had to squeegee out the usual spots where water puddled in the house after the rain storms. I was anxious to get the shingles on so I could sleep better when I heard rain in the middle of the night.

Adding Windows

(Did you know that Ply Gem sponsored the Saving Etta project by providing windows and sliding doors? I’m incredibly grateful and excited to show you the windows.)

Speaking of sleeping better, I couldn’t wait to get the windows and doors installed so I could prevent birds, animals, (and anyone else) from wandering into the house at all times. (Funny but not funny story: even after the windows were installed, I found a couple of birds had made a nest in the upstairs bedroom. They flew in where the soffit vents were to be installed. Luckily I discovered them before they laid eggs.)

One morning I showed up to work and found my framers installing the windows in the house. It was a happy day! Although watching them insert the double windows into the second floor opening was a bit nerve wracking. But, of course they made it look easy in this video I shot:

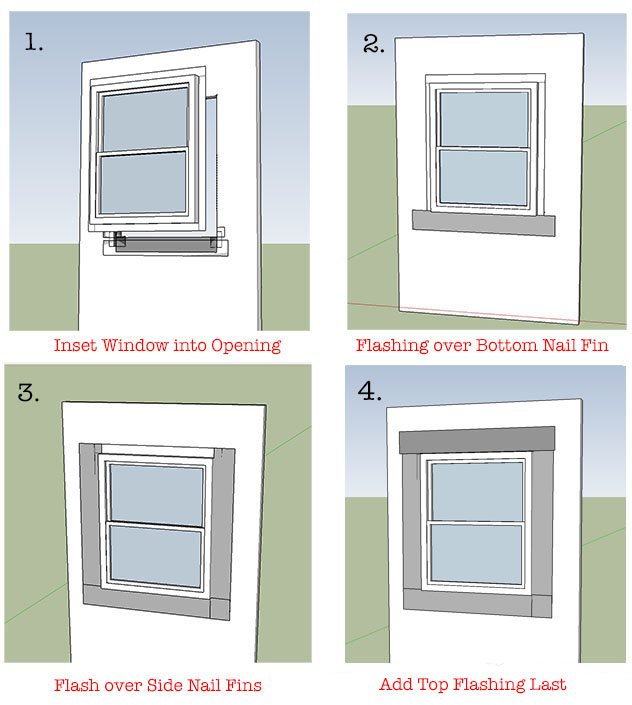

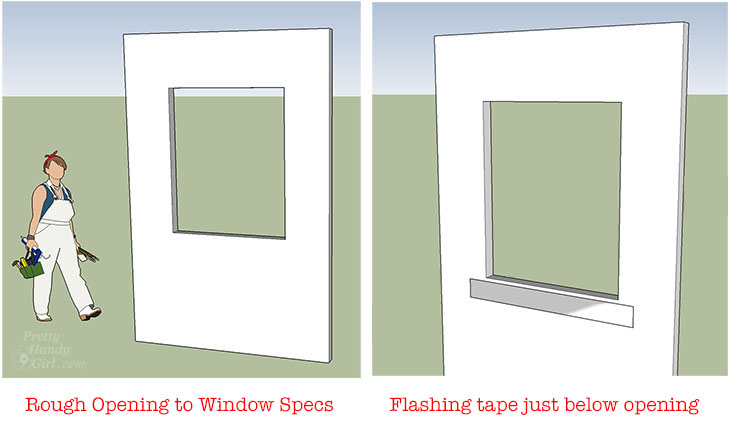

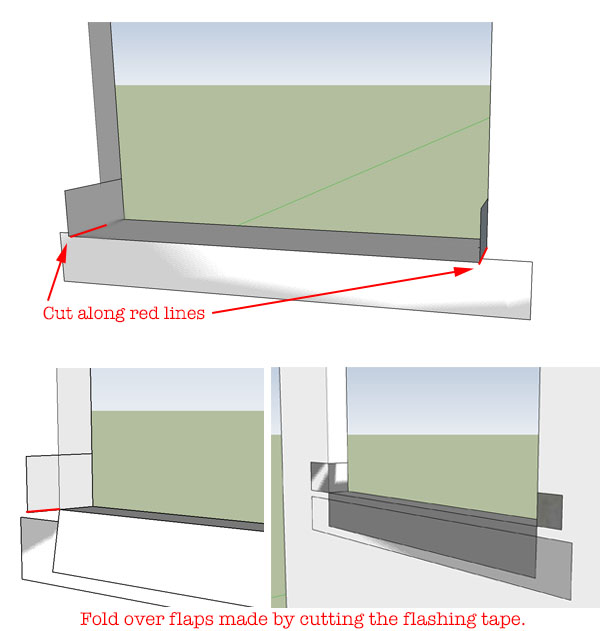

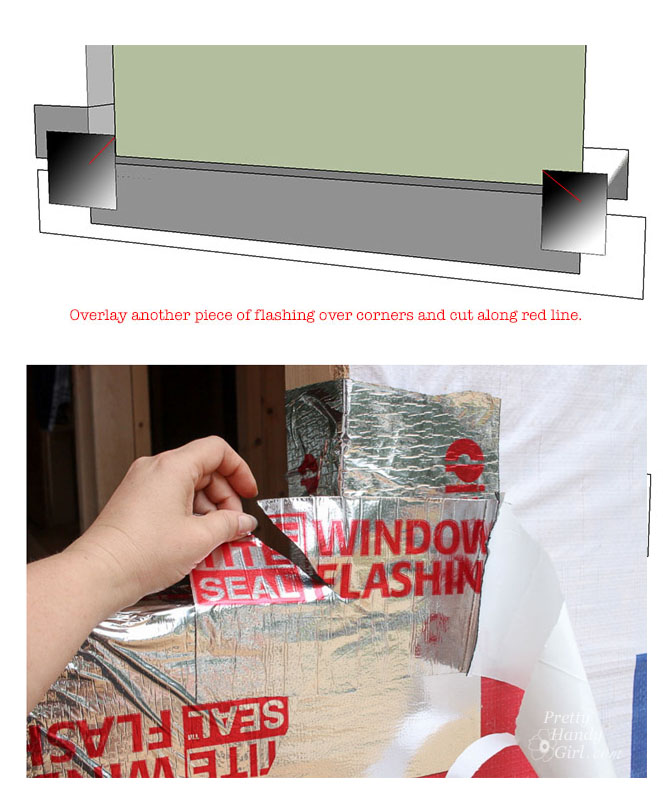

After all the windows were installed, they flashed the nail fins and prepared the house for siding. (You can learn how to install new windows by following this tutorial.)

The sliding patio doors were installed last.

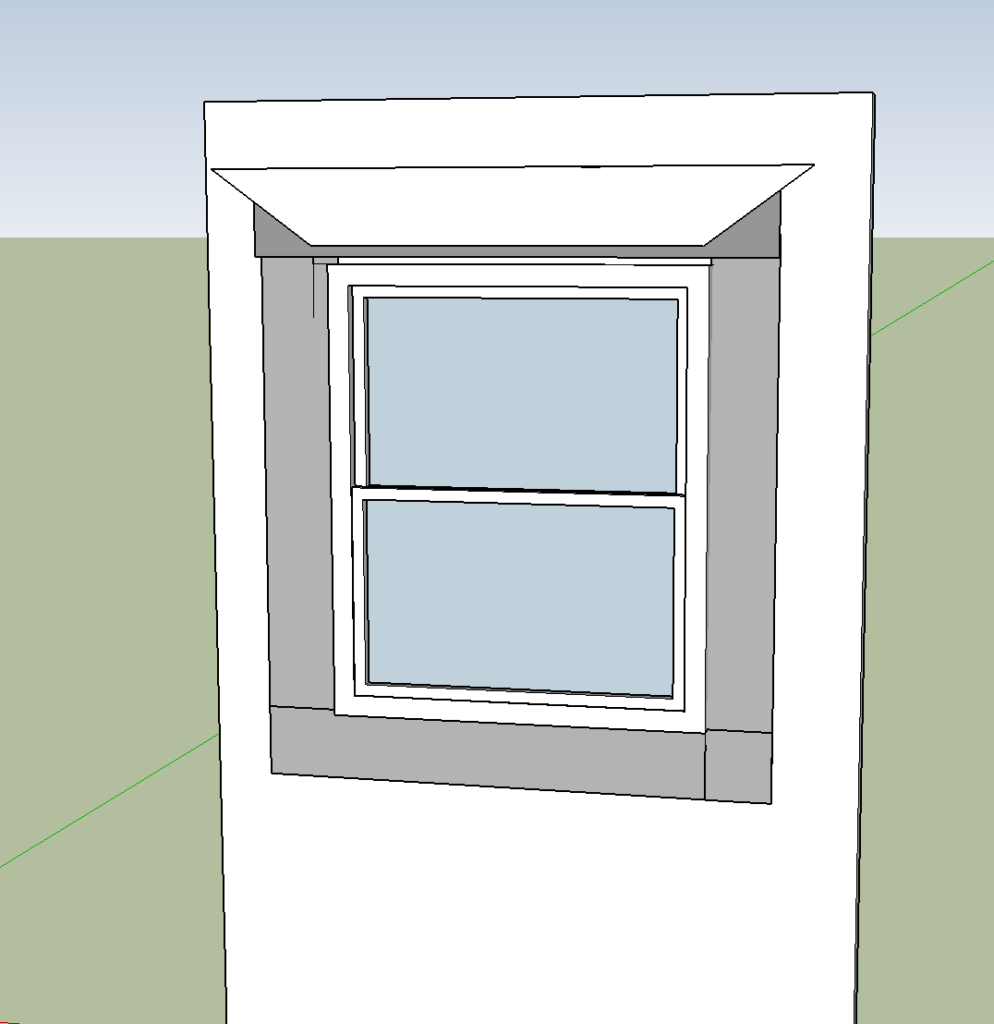

I am in love with these Plygem Mira Windows because they look like true divided light windows. The grilles are on the exterior of the glass creating a simulated divided light appearance. From a few feet away, you can’t tell they are replacement windows.

For a classic look, I chose white for the exterior, but for a more modern feel, the interiors are black. I can’t wait to see them once the drywall and trim has been installed and painted. They are going to look so sharp!

The windows slide smoothly up and down on their tracks. The original windows in the old portion of the house wouldn’t stay up and some were painted shut. They were in such bad shape I had to replace them. But, I knew I wanted the new windows to have something in common with the original windows: they are double hung (meaning the top window slides down too.) Did you know that double hung windows are actually designed to help cool a hot room? Back in the day, all you had to do was lower the top window and raise the bottom to allow hot air to escape out the top, and cool air could come in the bottom. By putting a fan in the bottom window, you could increase this natural air conditioning of a room. Read more about this scientific phenomena in The Craftsman Blog.

The Plygem Mira windows also tilt in for easy cleaning. I wish we had these windows on our own house, because it would make cleaning a lot easier.

The other new addition to the exterior was the louver gable vents that match Etta’s original vents. I ended up building five new gable vents. The original three were in really bad shape and were falling apart. But, I used them as the template, knowing I’d never be able to find stock vents that matched the original diamond shape.

Adding the Roof, Front Porch, and Siding:

It had been my dream to add a metal roofing on the entire house, but I nearly choked when I got the estimate. The cost was almost 5 times the cost of asphalt shingles. (I’m not talking about cheap three tab shingles, the quote was for dimensional architectural shingles.) As a compromise, I decided to add metal roofing to the porch roofs and the fireplace bump out. The rest of the house would get light gray shingles to match the raw metal roof.

As quickly as I could get the roofers started, they arrived to install the shingles. In no time, the house was water tight (with the exception of the areas where the side porch roof met the asphalt shingles.) The front and side porch couldn’t get metal roofing until after the siding installation and after painting. This would eliminate the risk of anyone walking on the metal roof and damaging it. Until the metal roof was installed (at a later date) we had a minor leak during a strong thunder storm. But, otherwise, the house was water tight.

Hey look at that picture above! Did you notice the new front porch? The framers built it back in the same style, shape, and size of the original porch. Now that the front porch is properly built (and tied into the house), it’s no longer at risk of pulling away from the front. Plus, now we can flash behind the siding to prevent water from seeping under the siding or around the porch roof. Although this had been an added expense, I knew it was the right decision to make sure this house survives another 100 years.

Interior Work:

While the exterior work progressed, I worked inside adding blocking in the bathrooms for the shampoo niches. I also needed to add a flat block for the ceiling fan on the 14 foot ceiling in the living room. Normally my framers would be responsible for these little items, but they weren’t pointed out until my plumber and electrician mentioned it. And since the framers were on to another job, it was up me to get it done! I’m finding there’s a lot of these punch list items a general contractor has to tackle to keep the project moving forward.

I also took the opportunity to frame a space in the mudroom around the HVAC ductwork chase. This area will eventually have a shallow storage box and key hooks inside. It’s a little something special I made with salvage materials from Etta’s walls.

This was also the perfect time to add blocking for the floating shelves in the kitchen. It’s always easier to have blocking to secure to instead of trying to find the studs.

While I was adding all the blocking, my electrician, plumber, and HVAC contractors worked tirelessly running wires, pipes, and ducts.

I definitely appreciate their hard work and the time they spent crawling under the house to get everything installed. After the lines were run, I did a little inspection of my own in the crawlspace before the city inspector came out. Just another day in the life of a general contractor.

Unfortunately our first rough in inspection was definitely “rough.” We failed all three inspections for relatively minor things. My subcontractors all came back and fixed the issues so we could call in a second inspection (which we did pass.) I won’t get into the nitty gritty of the inspections, but I will tell you that it’s true when you hear contractors complain about inspectors exerting their power. Regardless, I still believe in the importance of getting the proper permits and inspections when renovating your home.

Siding and Trim:

It’s amazing how much of an improvement the new siding and trim made to the house. As a reminder, this is the faded aluminum siding that was on the house when I bought it.

And this is the original siding that was hiding under the aluminum.

After the new fiber cement siding was installed, the house looked less “naked”. (I chose a woodgrain textured Allura siding over Hardie Plank because the wood grain texture was more prominent on the Allura siding and kept the look of old wood siding.)

The siding contractors worked for several days wrapping the house methodically, one side at a time.

By the time they were done, Etta was looking like a new lady and I finally felt like I truly saved her.

Believe it or not, I still didn’t have a front door installed until days before the siding contractors were finished. The framers came back to complete a few small tasks and installed the front door.

Do you remember this old door? Remember where I found it? I can’t wait to show you how I fixed the big crack in the panel.

Stay tuned to see what colors I chose for the siding, trim, and front door!

![]()

Disclosure: This post is a sponsored post for Ply Gem. It was written as part of their sponsorship of the Saving Etta project. I was not told what to write. All words and opinions are my own. I am very particular about the brands I work with, and only partner with companies that provide quality materials and/or services.

Time to install the window! Run a generous bead of silicone along the inside of the nail fin frame. Be sure to add additional silicone at the diagonal corner seams of the nail fin.

Time to install the window! Run a generous bead of silicone along the inside of the nail fin frame. Be sure to add additional silicone at the diagonal corner seams of the nail fin.