Hello, it’s Jessica here from Decor Adventures. This month I have what came out to be one of my favorite projects to date. It’s how to make your own light fixture using just wood trim and wax paper, and I promise it will look great in any room in your house.

Everyone loves Pinterest for inspiration and ideas, and I’m no exception. I was looking through my pins the other day and saw this one of a stunning (and I’m sure expensive) light fixture. I instantly thought how easy it would be to DIY that light and set out getting my supplies ready.

Materials:

(contains affiliate links)

For Wood Frame

- 3/4″ x 1/2″ pine wood

- Hand saw or Miter saw (or have it cut at the home improvement store)

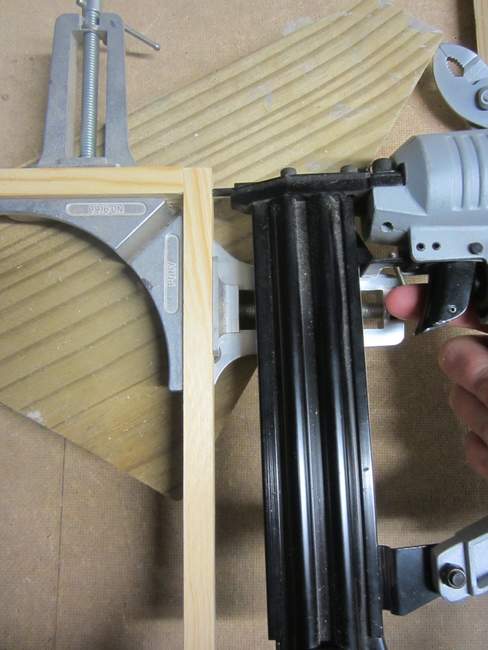

- 9166 CORNER CLAMP

- Nail gun and air compressor and nails

- Spray paint

- Old lamp shade or washer top of wire lamp shade frame

- Hot glue gun and glue sticks

- Gorilla tape

- Lampshade Pendant Kit

For Capiz Shells

- Wax paper

- Iron

- Circle Punch

- Sewing machine and thread

- Scissors

Instructions

For this tutorial, you’ll learn how to make and attach the black wood frame to a light pendant kit after you make and put on the faux (wax paper) capiz shells. For a step-by-step of how to make the shells, see my post on how to make a wax paper capiz shell chandelier and follow the instructions on how to iron together the wax paper and sew them together.

How to make the wood “frame” for your light fixture:

Cut your 3/4″ pine trim into 12 pieces. Eight of them will be the same (shorter) length and 4 of them will be the same (longer) length. My pieces are 9 1/2″ and 14 1/2″. Make sure your 8 smaller pieces are the exact same length and same goes for your longer ones. If they aren’t, your 3-D frame will not fit together perfectly.

To assemble your boxes perfect for easier nailing, use a miter corner clamp. These are available at the home improvement store for about $25 and can be used for a lot of different projects. Insert two of your smaller pieces into each side of the clamp, making sure the ends line up.

Using your nail gun, nail into the wood to secure a corner.