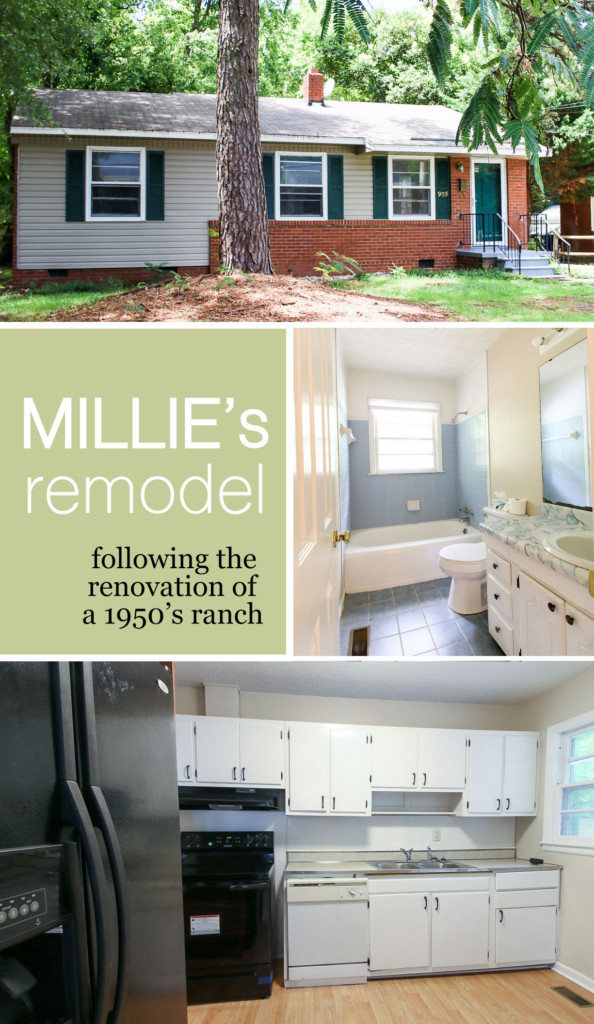

Get a load of this transformation! See Millie’s Remodel and her exterior front reveal. Plus, I’m sharing tips to help you keep your home protected from termites when landscaping.

Millie’s Remodel Update: Exterior Front Reveal

This update of the Millie’s Remodel project is sponsored by Corteva, the makers of Sentricon. I’m grateful to have Sentricon on board as a Millie’s Remodel sponsor!

Although I still have a lot to catch you up on inside the Millie’s Remodel house, the exterior siding, brick, and front door has been painted. I chose a pretty bright blue for the front door. It’s Loyal Blue from Sherwin Williams.

I built the shutters using leftover tongue and groove planks from the porch overhangs. I promise to share a tutorial for you in the near future.

And I added a modern address plaque beside the door. Also, a DIY I’ll share a tutorial for later.

Although the shutters have been hung and the house numbers look amazing, I feel like something is missing. The house feels a bit naked from the waist down if you catch my drift. It needs some landscaping!

Unfortunately, I’m a little over budget on all the renovations at Millie’s Remodel, so I need to save some money on the landscaping. I decided to plant a few bushes out front and call it done.

Budget Landscaping for a Mid-Century Modern House:

With my budget being under $200, I was able to put in some foundation plantings and one feature plant to give Millie a more finished look outside.

I planted three Fatsio Japonica bushes (the wider bushes with bigger leaves).

Between the Japonicas, I planted two Golden Ticket privet bushes. They should fill in a little over time, but for now, they certainly help ground the house.

For the feature item, I chose a pretty yellow Amber Gold arborvitae for the small bed between the front door and the driveway. I like the color and the tall skinny look of this tree. When full-grown it may be up to 5′ wide and 10′ tall. But, hopefully, it won’t reach full width and can stay a little narrower. I’ll have to keep an eye on it and trim the sides if it starts to get too big.

Luckily, I had a pile of wood chips in the backyard where I had to take out a large rotted tree that was hanging over the house. I was able to use the chips as fresh mulch around the plantings.

Although it’s hard to tell, in the above photo, I kept a barrier of bare earth (and no wood chips) against the foundation of the house. Why? Let me take a moment to talk about how to landscape while keeping your house protected from termites.

Landscaping While Keeping Your Home Termite Free:

I know we live in an area that is overpopulated with termites, so I’m very careful about protecting my homes from conditions that could lead to a termite infestation. Most plants need moisture to stay alive, but unfortunately, termites love wet mushy wood because it’s easier to chew and more tempting! For that reason, it’s important to pay attention to moisture around your home’s foundation. All the tips below will help you reduce the likelihood that termites will find your home tasty.

- When spreading mulch around plantings, keep it away from the house. Leave at least a one-foot perimeter along the foundation clear of mulch and other organic matter

- Plant bushes so as to maintain a three-foot clearance from your home (be sure to look at the mature height and width information on new plantings)

- Never pile firewood, lumber, mulch, soil, or other “termite-friendly” matter against your house

- Don’t use wood timbers or lumber to create garden beds against your house

- Install gutters and use downspouts to move water away from the foundation

- Always make sure your land is graded with a slope away from your house

- Keep gutters clear of debris to prevent them from overflowing.

- Contract with a good termite treatment company (you can read how I chose Sentricon in this post.)

- Keep up with scheduled inspections with your termite company.

![]()

My local termite company that installed the Sentricon system came back two weeks ago to check on the system to see if there was any termite activity and inspect the bait stations to see if they needed to be replaced. My technician was able to find most of the bait stations from the map he created during installation.

![]()

But, if the stations were buried, he could use the detector to find them.

![]()

You can learn more about the Sentricon system and how it’s installed by watching my previous video:

We saw some minor evidence that they had found the stations. This is good because it means they are feeding off the bait stations and taking it back to the colony.

![]()

Unfortunately, the memory card in my camera was corrupt, or I’d show you the bait station after almost a year. Luckily, Sarah has an excellent photo of her Sentricon bait station after being in the ground for almost a year.

![]()

A Look Back at Millie’s Front Exterior Transformation:

Together, I think the landscaping (although only 6 plants and some mulch) and painting made a big difference. We should look back to when I first bought the house. Remember how she looked? The greenery you see was all weeds!

Then, after painting, she looks great, but still needs some architectural pizzazz.

Finally, the shutters and painted front door made a big difference, but she was a tad naked around her base.

Now she has some beautiful modern greenery out front.

Did I do okay on my minimal budget?

Disclosure: This is a sponsored post for Corteva, the makers of Sentricon. I was provided complimentary termite protection for a year and was compensated for my time and efforts to promote Sentricon. I was not told what to write. All opinions are my own. I am particular about the brands I represent and will always let you know when you are reading a sponsored post.