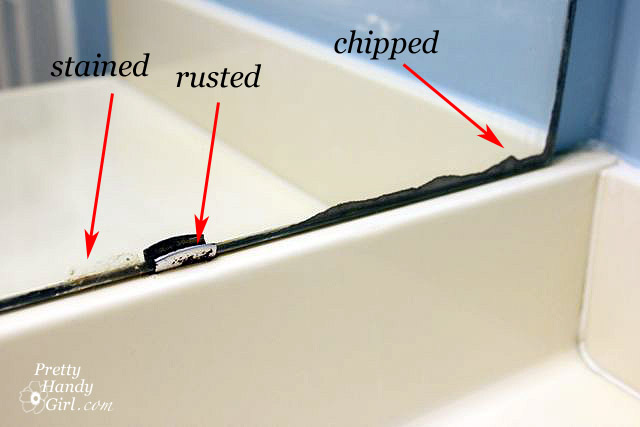

Do you have an ugly builder’s mirror? I’m betting about 85% of you do. The other 10% were lucky to buy a home that has a beautifully framed mirror. And the remaining 5% either made or bought a new mirror with a frame! When I was first introduced to MirrorMate on Kate’s blog, I could barely contain my excitement. There was finally a fix for the ugly builder’s mirror in my kids’ bathroom {happy dancing}! I could finally say adieu to the stained, rusted and chipped behemoth in the bath and yet I wasn’t adding anything to the landfill in the process!

Bethany, who works for MirrorMate, helped me pick out the perfect frame for our bathroom. And shipped it as soon as the frame was available. Unfortunately, the frame arrived right before I left to surprise my sister in Ca. Then I came home and got deathly ill. So, the poor frame sat in our garage for a month. As soon as I started feeling better I jumped right into the bathroom makeover project. I have to tell you, the makeover was inspired by the beautiful MirrorMate frame. I just couldn’t put that beautiful frame into the fishy bathroom. It just would look like the grown up in a child’s playground.

Putting the frame together and framing the mirror was a piece of cake. Here is how we did it:

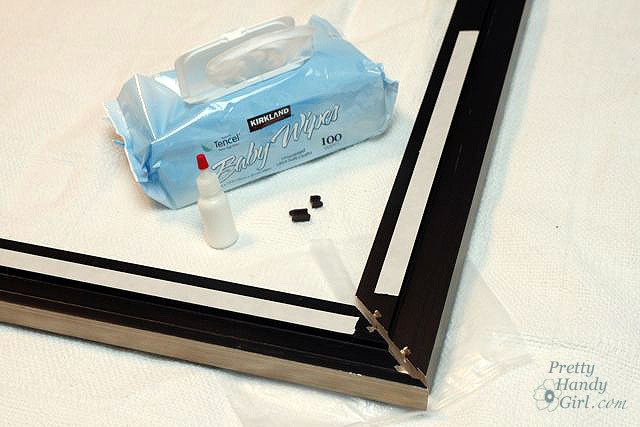

1. Unpack the MirrorMate and accompanying supplies.

2. Spread the frame and pieces out. Use wax paper (or old cereal bags) under the corners to protect your work surface from the glue.

3. Glue each corner.

4. Insert the small connector pegs into the slots at the corners. You might need a hammer to lightly tap them in.

5. Wipe off any excess glue with a damp rag (or baby wipe).

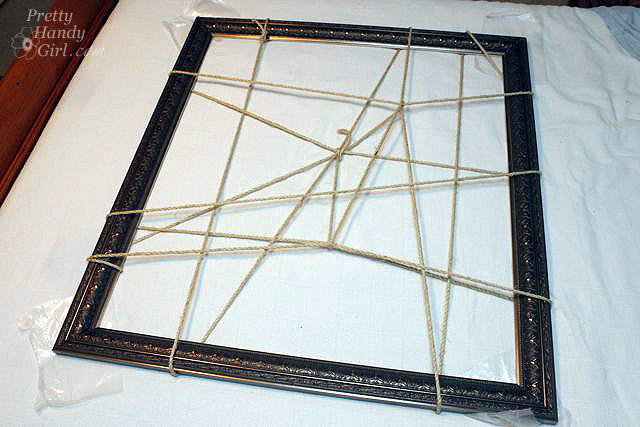

6. For added strength and to hold the frame while it dried, I chose to “clamp” my frame by typing rope around it. This was not a necessary step, but I think it helps insure a tight joint, so I did it.

Please tell me that I’m not the only one who started singing. “Spiderman, spiderman, does whatever a spider can, spins a web…”

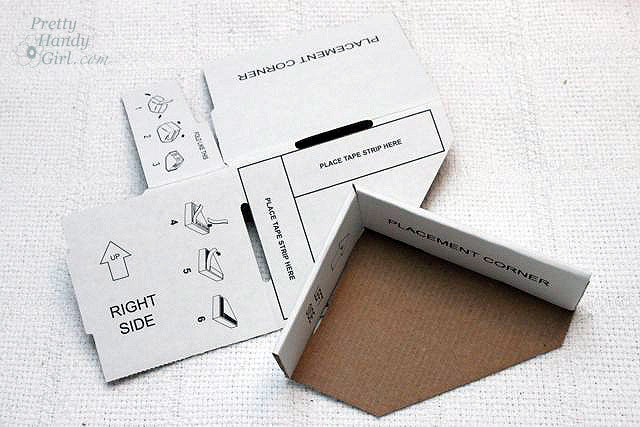

While the frame is drying, assemble the cardboard guides for the MirrorMate installation.

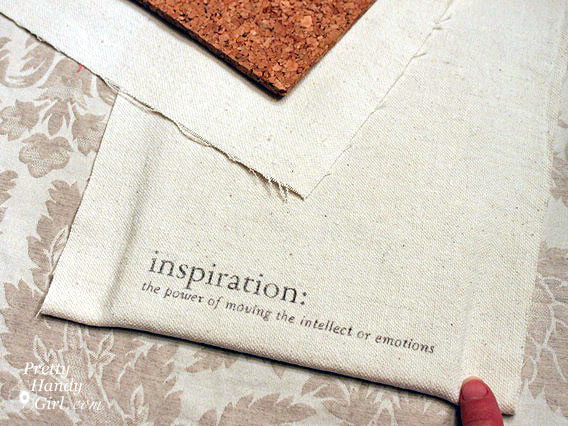

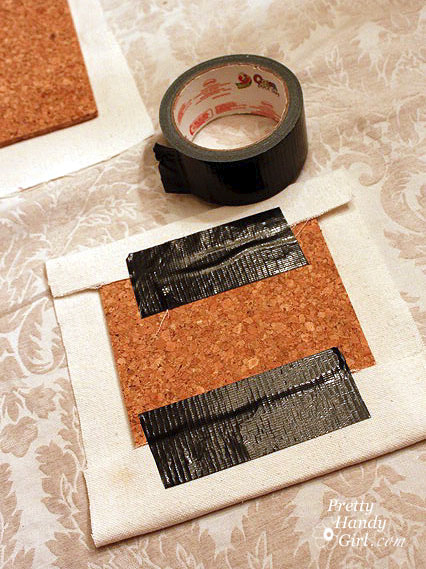

Add the double stick tape to the back as shown in the directions:

After allowing the frame to dry for an hour, get your DIY partner to help you move the frame. You must be careful not to lift or carry the frame by the corners or it could come apart. I left the rope on it until we moved it into the bathroom (just to be safe.)

Clean your glass with rubbing alcohol (especially where the frame will adhere to the mirror.)

Put up with your handsome assistant insisting on reading the directions (even though you already did and are anxious to move along.)

Have your assistant hold up the frame and then have fun telling him to move it to the left. No, wait a little to the right. Well, maybe back to the left. {Hee, hee.}

Level the frame.

Insert the corner guides directly into the top two corners. Be sure the guide is touching the frame’s inner edges.

Remove the frame and then peel off the tape backing.

Then lift the frame back up with the help of your assistant. Align the frame onto the corner guides and press firmly onto the glass. You only have one shot at this, so go slow.

Remove the corner guides and the glue strips from the mirror.

Now stand back and admire your newly framed mirror! GORGEOUS, don’t you think? And the installation was a snap (or should I say a stick. LOL!)

No one will ever know that you are hiding a dirty stained, chipped and rusty secret underneath!

One final look at the finished product and a sneak peek at the finished bathroom. I’ll be sharing with you the board and batten tutorial soon.

One final note: I have to warn you, DO NOT put painters tape on your mirror or you will be crying the blues like I was.

I immediately contacted Bethany to see if she could send me some touch up paint. I can’t even tell you how helpful she was and when she reported that it was actually hot press leaf on the frame and not paint, I figured I’d be doing some creative treatment on the side. But, instead, she insisted on sending a new frame immediately (which arrived 2 days later!) MirrorMate has the best customer service and she told me “We want our customers to be happy with their purchase, even if that means sending a new frame.” Wow, now that is a company I want to do business with!

Disclaimer:

I was sent a complimentary MirrorMate frame for a product review. I can honestly say that this post reflects my opinions and I was not swayed to write a positive post. Nor was I paid to write this post. For more information you can read my disclosure statement.