The Real Facts about Using Pallet Wood

Pallet wood is EVERYWHERE! It’s hard to browse Pinterest without stumbling on a pallet wood project. Everyone and their cousin’s best friend have experimented with and built amazing things using pallet wood. Admit it, you’ve seen those beautiful projects and began driving behind your local shopping centers looking for those wooden freebies. Sadly, most pallet project creators won’t tell you the Real Facts about Using Pallet Wood. Put your mind at ease knowing that I’ll tell you the bare wood truths about using pallet wood. Then the next time you find yourself in a back alley attempting to haul that pallet into your trunk, you can weigh the facts.

A few weeks ago I slaved for over an hour trying to get those free pallets to relinquish their prized slats. As I bent over one pallet, sweating and swearing, I asked myself, “Wouldn’t it have been easier to spend $2-3 per board at Lowe’s?”

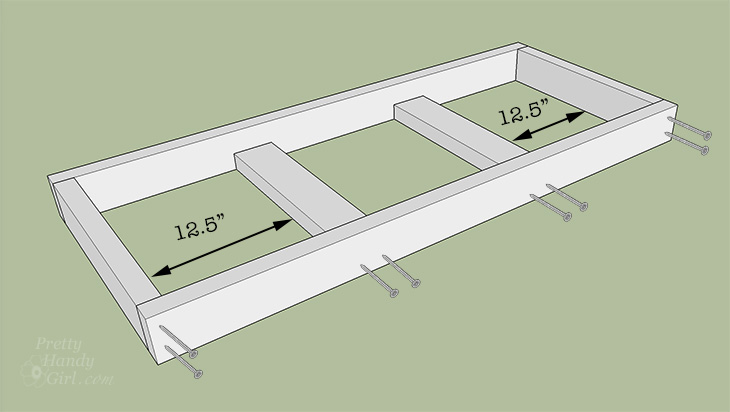

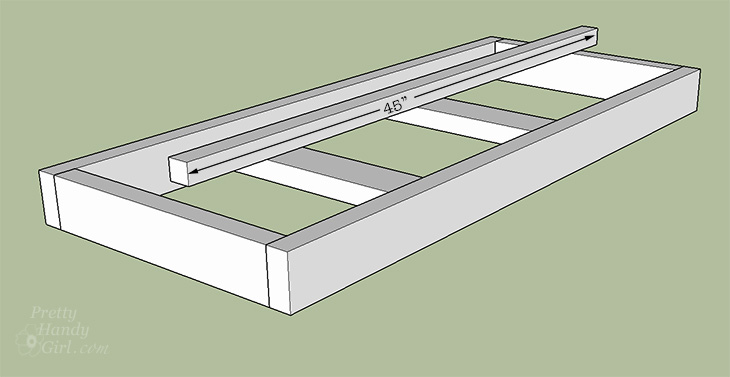

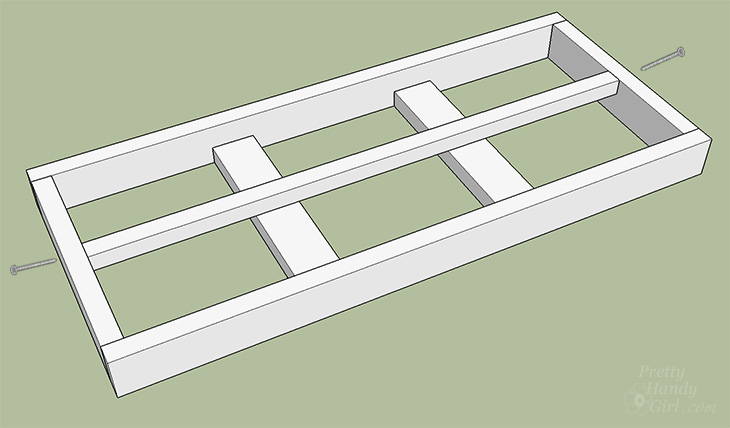

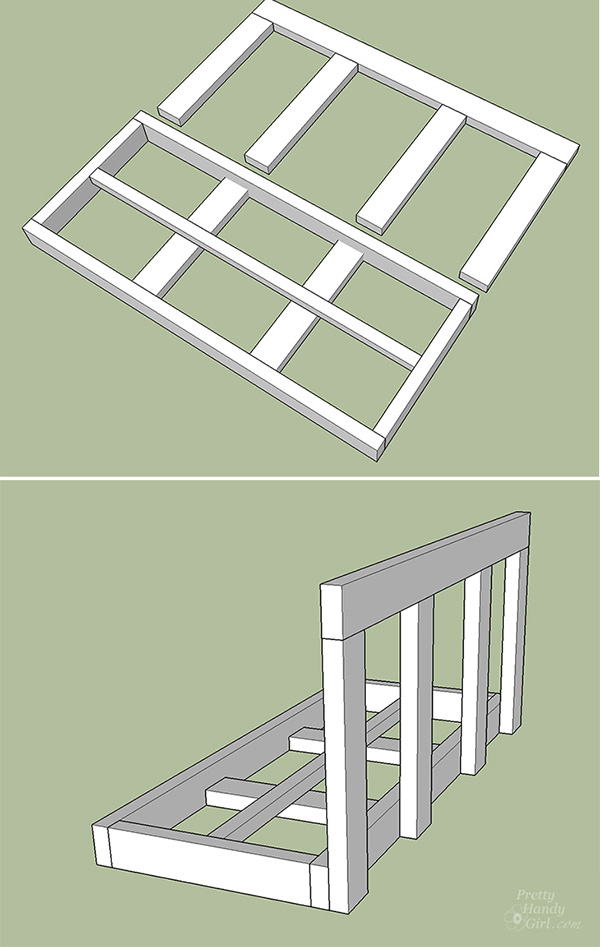

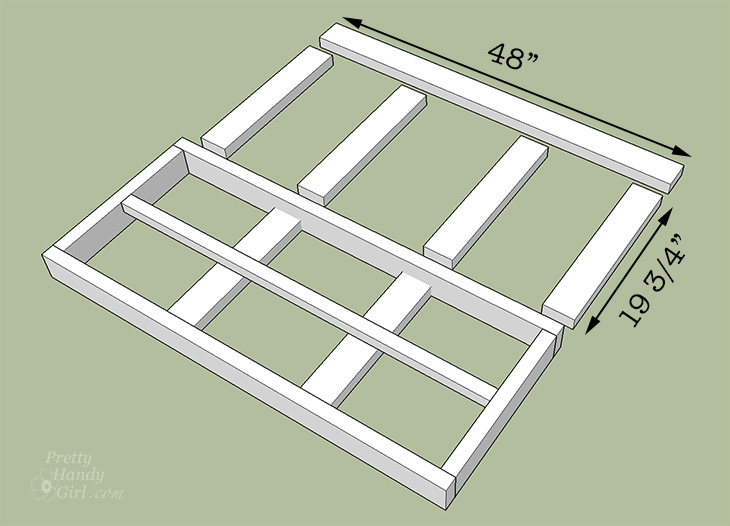

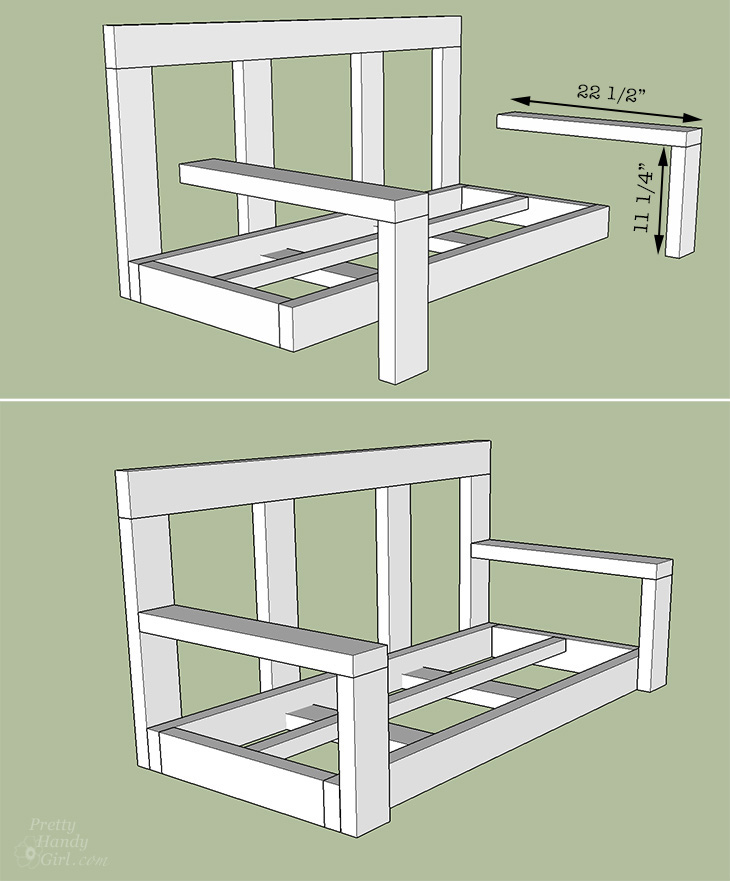

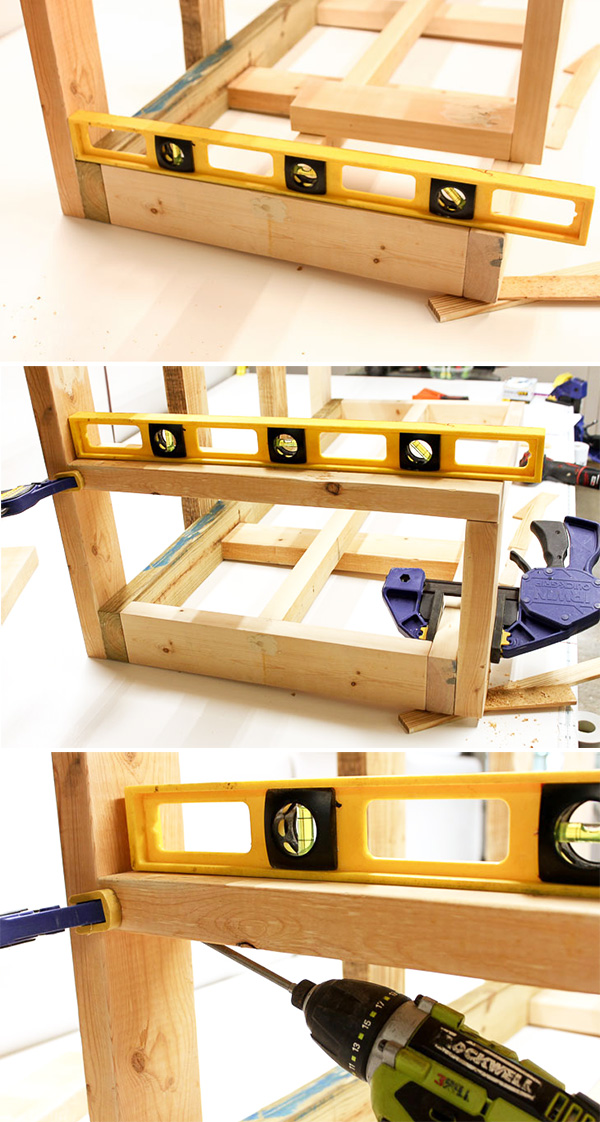

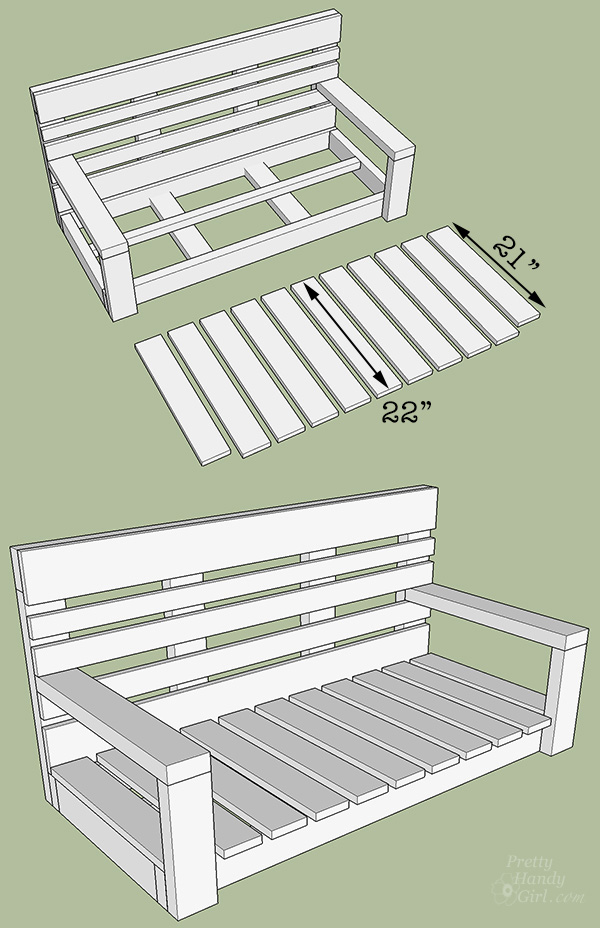

As I was building this porch swing with pallet wood, I began to create a list of the pros and cons of using pallet wood. By the time the paint had dried on the swing, I knew I had to be honest and share with you these facts so you could determine if using pallet wood is worth the effort and risks.

Benefits of Using Pallet Wood:

1. First and foremost, pallet wood is usually FREE!

2. Environmentally speaking, you are keeping pallets out of the landfill. Yay for being eco-friendly.

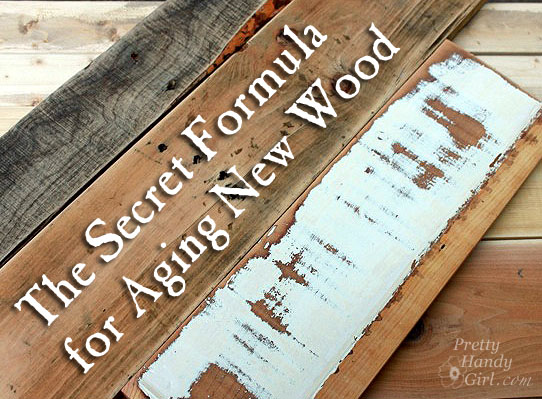

3. Pallet boards often have a beautiful rustic patina (pallet board on the left, new pine board on the right.)

4. The wood is usually strong.

5. It’s stylish and popular because the rustic industrial look is in style right now.

6. Everyone’s doing it—wait a minute! Just because everyone is doing it doesn’t mean you should jump on the bandwagon!

Why You Might NOT want to use Pallet Wood:

1. Actually removing pallet wood planks is difficult. Pallet wood is held on with spiral nails that are hard to remove without breaking or damaging the pallet wood. (Not to mention breaking your spirit!) Using a hammer and/or a regular pry bar is tedious and not super effective. You would be better off using a deck wrecking tool like this one. (affiliate link)

2. Harvesting pallet wood often damages the planks or causes them to split. You can salvage pallet wood using a circular saw and this technique, but your boards will end up being shorter.

3. Yes, you can use a reciprocating saw and/or multi-tool with a metal cutting blade, but getting a clean cut is difficult (usually you cut into some of the wood). And you are left with cut off nails that need to be removed, filed down, or avoided.

4. Pallet wood may be treated with chemicals to prevent deterioration. If you can find markings on the pallet, you might identify if the pallet was treated by looking for these codes.

5. You can never truly be sure what has spilled on the pallet and has absorbed into the wood. I’ll let your imagination wander. You should consider how you’d feel if you found out the pallet had a chemical spilled on it, animal urine, feces, or raw food. (For this reason, it’s a good idea to seal the wood with a polyurethane or polycrylic if you decide to use pallet wood.)

6. Pallet wood is not perfect. It usually is low grade wood and has dings, cracks, splits, or large splinters.

7. Pallet wood may have staples and tacks that will need removal.

8. Pallet wood isn’t normally smooth and may need extra sanding to get a usable plank.

9. Pallet wood is rarely straight.

10. The planks aren’t usually a uniform thickness. To achieve uniform thickness, they’ll need to be planed. But, make sure you have removed all nails and staples or you risk damaging your planer blades.

11. When you’re done harvesting pallet wood you’ll need to find somewhere to dispose of the pieces you don’t use. Most waste companies won’t take pallets because they label them as construction waste.

Now that you know the pros and cons of pallet wood, you can weigh them and decide if you want to use that free pallet wood or buy new boards from your local home improvement store.

After all, pine framing lumber is cheap! And luckily, you can fake the age of new wood using this tutorial:

Lest you think I’m scaring you away from using pallet wood, here are a few cool projects you can make with it.

Clad walls with pallet wood to create a beautiful feature wall:

Use pallet wood to create a bread crate display shelf:

Or make a serving tray out of pallet wood (be sure that your pallet wood is clean, chemical free and always use a plate under the food.)

What are your thoughts and experiences with using pallet wood? Have you made anything using pallet wood? Would you do it again? Let’s open up the conversation in the comments below!

![]()

How to Make a Super Simple Bar Stool

How to Make a Super Simple Bar Stool

How to Build a Floating TV Shelf

How to Build a Floating TV Shelf

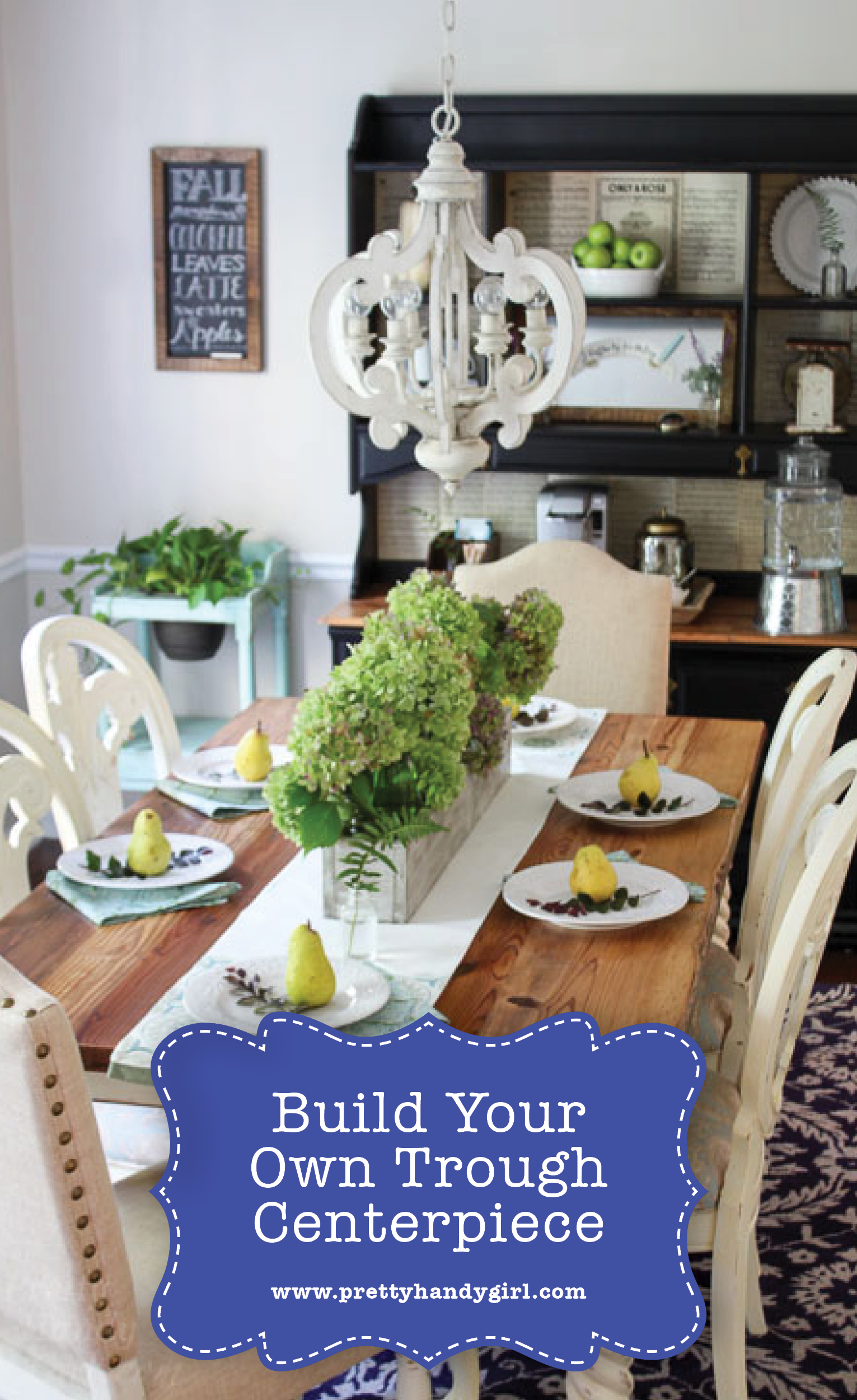

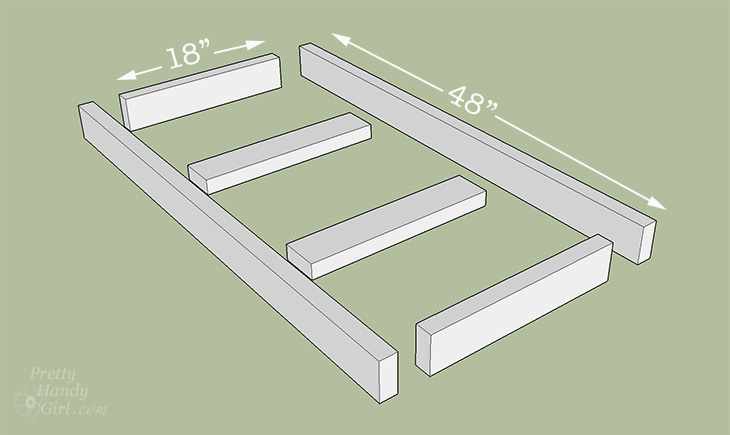

Build Your Own Wood Trough Centerpiece

Build Your Own Wood Trough Centerpiece