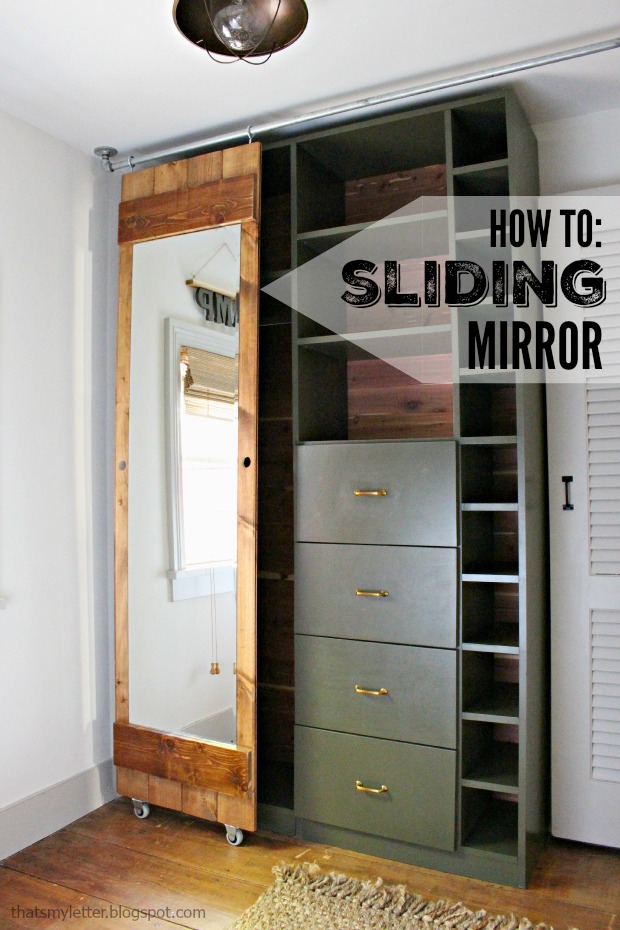

How to build a sliding mirror door:

Hello Pretty Handy Readers! Jaime here from That’s My Letter and today I am sharing a sliding mirror project that is the finishing touch on my newly made over walk-in closet. I will show you how to build a sliding mirror door using wood, wheels and pipe fittings.

This sliding mirror is my solution to a small walk-in closet with no wall space and no back of the door option for a mirror. The mirror slides across the room on stationary wheels and a galvanized steel pipe track.

My pipe extends beyond the built-ins (mainly because that’s the pipe I had on hand) but this also allows for full access to the built-in compartments.

In the photo below you can see the pipe extends beyond the built-ins at the ceiling:

Simple finger pull holes allow you to glide the mirror along the pipe. You could get fancy with hardware here but I took the minimalist approach.

Stationary wheels keep the mirror in place while eliminating the need for any lower track system.

Hello super slim profile! The whole mirror and wood support is only 1 1/2″ thick so the mirror does not protrude out into the room.

Ready to make this clever sliding mirror? Let’s get to it… Read more