How to Use a Kreg Jig

Hey, look at this! Tool Tutorial Friday is back! Today I have a great tool for creating strong joints when building with wood and furniture construction. Today I’m going to show you the simple tutorial for How to Use a Kreg Jig. If you don’t have one yet, you need to purchase one ASAP! This little tool is my go to for for building furniture, frames and just about anything that needs a tight joint.

(I’ve included affiliate links in this post for your convenience. I earn a small percentage from a purchase using these links. There is no additional cost to you. You can read more about affiliate links here.)

I use the K4 Kreg Jig It didn’t take me long to figure out how to use it, but I know it would have been helpful to have a step-by-step tutorial when I was first learning how to use a Kreg Jig. For your convenience, this is a quick tutorial.

I was first introduced to the Kreg Jig by my friends Ana White and Rayan with The Design Confidential. These two DIY ladies opened my eyes to pocket screw joints. Be sure to check out their blogs for more tips from the masters!

The Basics on How To Use a Kreg Jig

First you will need to measure the thickness of your board. The wood I used was 3/4″ thick. It is important to actually measure your stock because what is sold as a 1″ thick board is usually about 3/4″ thick. You should always measure any wood you buy regardless of how it is labeled. The wood may shrink or deviate from the standard size.

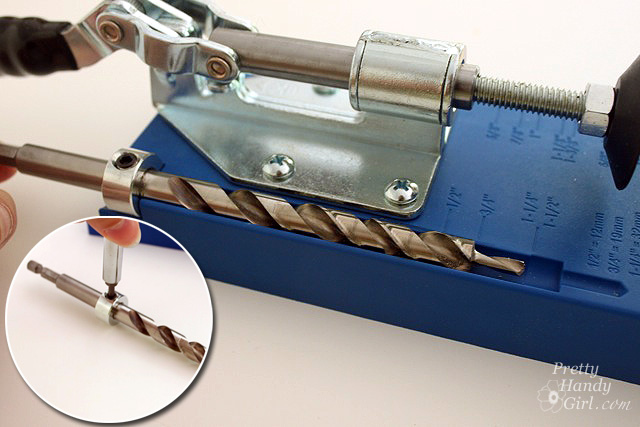

Use that measurement to set the depth collar on your Kreg drill bit. The Kreg Jig I have has this handy guide built into the base. Simply set the drill bit into the groove and line up the step (the spot where the drill bit goes from wide to narr0w) with the measurement that corresponds to the thickness of your wood. The depth collar is adjustable with a hex bit.

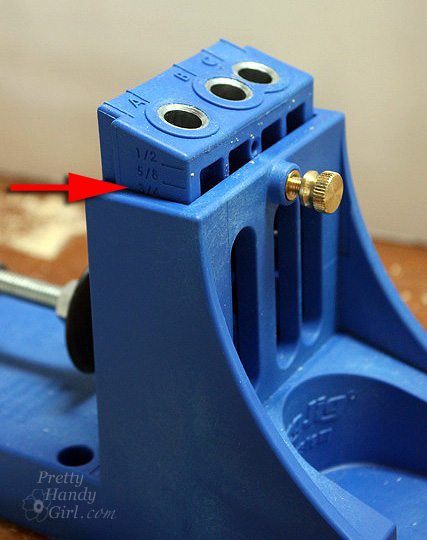

Next you want to set the jig placement, also based on the thickness of your wood. You’ll notice the numbers on the side of the jig. Loosen the gold thumb screw and raise or lower the hole guide until it corresponds to your wood measurements. Re-tighten the thumb screw.

If you are joining two different thicknesses of wood, use the thinner board to set your measurements. You may want to vary your screw size. Kreg Jig has this handy chart to find the correct screw lengths (the left vertical side in the chart is the thickness of the board receiving the pocket holes. The horizontal top edge is for the thickness of the board that is being screwed into.)

The next thing I do is clamp the jig to my workbench. This isn’t absolutely necessary, but it helps hold things steady.

Set your wood into the jig, line up the end you want to drill holes in at the bottom of the jig. Then press the clamp lever towards the board to clamp it in place. You may need to turn the clamp screw to tighten or loosen it for a secure hold.

Insert the Kreg Jig drill bit into your drill. Start your drill in the forward motion. Drive the bit into the pocket hole guide. Stop at the depth collar on the bit.

For strong joints always use at least two pocket holes. One will only act like a pivot point for the joints to twist and turn.

Remove the drill bit and unclamp the wood.

To complete your joint, clamp the pieces together and drive pocket hole screws into the pocket holes and into the second piece of wood. Choose the screw that is recommended for your material thickness:

1/2″ material = 1″ screws

3/4″ material = 1 ¼” screws

1 1/2″ material = 2 ½” screws

There is a clamp that comes with the K4 Kreg Jig (you can use it to clamp on top and bottom of the joint), but I prefer a larger clamp like this 24″ IRWIN clamp so that the wood doesn’t get marred.

To conceal the pocket holes after your joint is completed, purchase the Kreg plugs. Or you can fill them with Bondo (Yes! Bondo works great as a strong wood putty! Just remember to allow for drying time and sanding when using Bondo.)

And that’s the basics for using a Kreg Jig! You can save some money if you want to purchase the Kreg Jig Jr., but if you plan to do a lot of building, I recommend the Kreg Jig K4 for easier joinery. It has the removable pocket hole guide. The price usually runs just under $100.

Want to learn how to use more tools? Grab a tool and learn now:

Check out these projects using a Kreg Jig:

DIY Open Frame Radiator Screen Cabinet Doors:

Pergola with Trellis Trash Can Screen:

Fireplace Insert Draft Stopper:

Disclosure: I was not paid to endorse Kreg Jig. I purchased the jig with my own money and wrote this tutorial to give my readers the basic tips for using one. As with all tools, be sure to read your owners manual and familiarize yourself with your tools. I am not responsible for any errors or omissions in this tutorial. This post contains affiliate links.

Clamps? 🤦🏼♀️ I bought a kit similar to the Kreg. Harbor freight. Was being a skinflint. Anyway, after a year, I used it this morning to build a bistro type table for my little house. Found out quick. Level work space…..clamps! I know that I am going to love it once I feel a little more comfortable. I have a couple of cabinet doors that I cut into waiting in line. A headboard! Just need lots more screws….. thanks for the great tutorial. I just might ask for a Kreg for Christmas. Got diamonds and a drill – couple of years ago. Best gifts ever!

Thanks for the step by step instruction on the Kreg 4 Master Jig. I have had mine for thee years and have never used it.

Why do you start the instructions by saying,” You will need to measure the WIDTH of the board ” Is it not the thickness of the board you use to set the system up? What dose the WIDTH of the board have to do with it?

Good catch Sam. Editing now.

Can you use this to put together mitered corners?

Definitely! I’ve used it on many mitered frames.

For simple cabinet building which needed tight joints, I always pulled out my hands. But after reading this tutorial I think it may be easy for me to use.

Honestly, I’m really scared of heavy wood work job & equipment or anything of that sort. it c=scare me a lot. I don’ consider it all, I would rather do the simpler stuffs around, But this tutorial is quite convincing and helpful too. I may have a try at it, who knows, I may get it and realize tha there’s nothing really in it,. Thanks, B

I got a kreg jig a few years ago for a very specific project but have found it to be a necessity in my shop since. Great article, I would not want to be kreg-less for any project now!