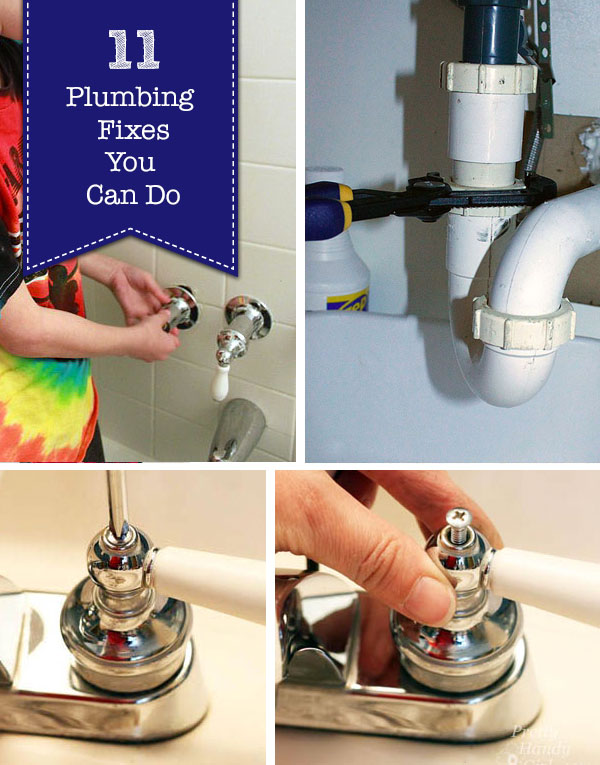

11 Plumbing Fixes You Can Complete

When I tell people that there are few reasons to call a plumber, they are usually doubtful. Today I want to show you 11 Plumbing Fixes You Can Complete on your own! Whether you have a leaky faucet, a slow drain, or a malfunctioning toilet —today you’re going to learn how to solve all those plumbing issues and more! Ready to get started? No plumber’s crack required. 😉

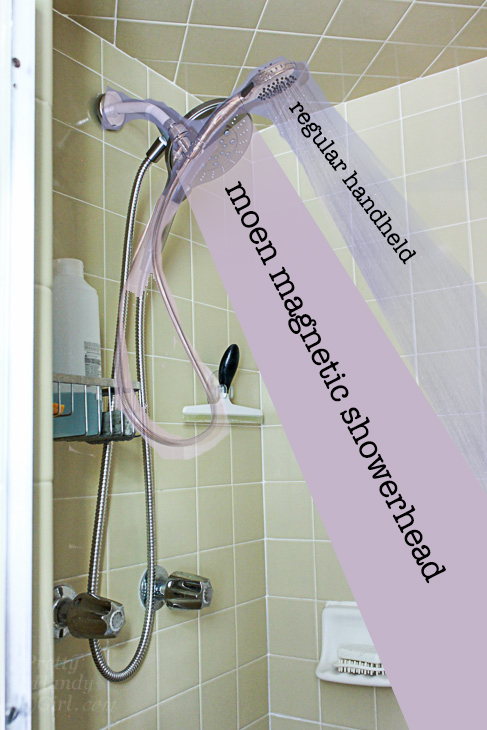

Did you know you don’t have to live with a drippy, rusty, or poor functioning shower head? Learn how to Easily Install a New Shower Head for a simple bathroom update.

Shower valve stems wear out, it’s as predictable as rain on the day you want to rock a killer hairdo. Unfortunately I can’t help you with your bad hair day, but I can teach you How to Repair a Leaky Shower or Tub Faucet in no time. (Just so you know, my eight year old helped me with this fix. If he can do it, so can you!)

Unfortunately, clogged sinks happen to the best of us. Next time your sink basin refuses to drain, try this Non-Toxic Drain Opener. Plus, you can find the ingredients in your pantry (or buy them because they are inexpensive and chemical free!)

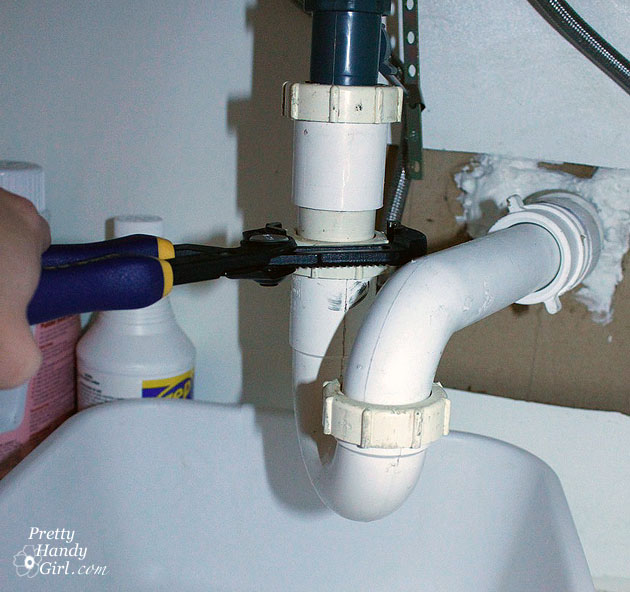

Oh $*+! Did you drop your favorite earring down the drain? Put down the phone, you can easily learn How to Retrieve Items Dropped Down the Drain by following these few steps. And hey, even if it isn’t your favorite earring, you’ll want to remove the item to prevent a future clog.

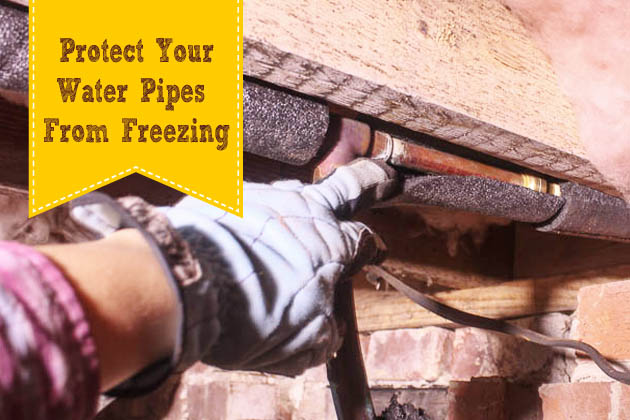

Replacing Water Lines with Braided Metal Hoses is as easy as attaching your garden hose. But, it can save you thousands of dollars in damages from a burst water line. If you don’t have the braided metal type of hoses, you’ll want to learn how to replace them.

Drip, drip, drip! Is that leaky faucet keeping you up at night? I have a 10 minute fix that will bring you sweet dreams and a lower water bill. Follow this simple tutorial for Fixing a Leaky Faucet.

Sometimes the simplest and least expensive solution for a leaking faucet doesn’t fix the issue (especially if the faucet has been leaking for a long time.) Don’t fret, you can still stop the dripping without replacing the entire faucet or resorting to calling a plumber. Learn how to replace the valve stems in just a few minutes.

Years ago, my mom’s kitchen sink sprayer started spraying us! We tried to clean the head, but ultimately gave her faucet the boot. Learn how you too can install a new sink faucet in no time.

Occasionally a sink drain assembly will fail on you. You don’t have to wash your money down the drain by hiring a plumber. Instead, see how easy it is to replace a sink drain.

Toilet broken? Rarely does that mean you need to replace your toilet. If your toilet is in need of a repair, here are several fixes to put it back in working order:

- How to Replace a Broken Flush Lever

- How to Replace the Fill Valve

- How to Replace the Overflow Tube and Flapper

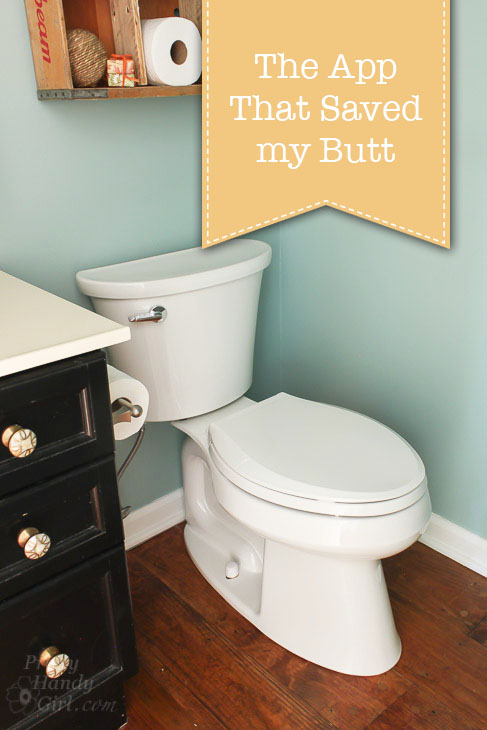

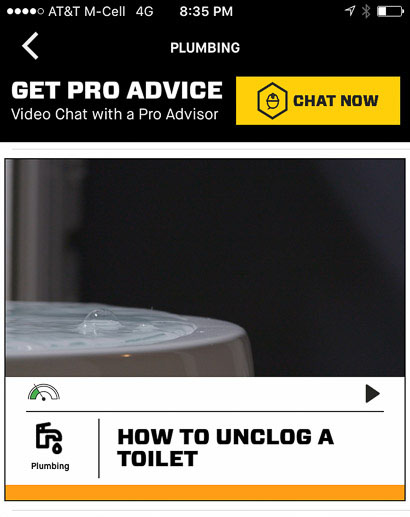

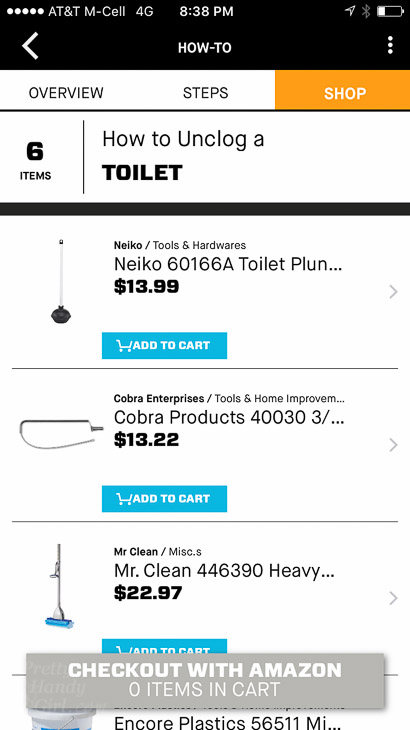

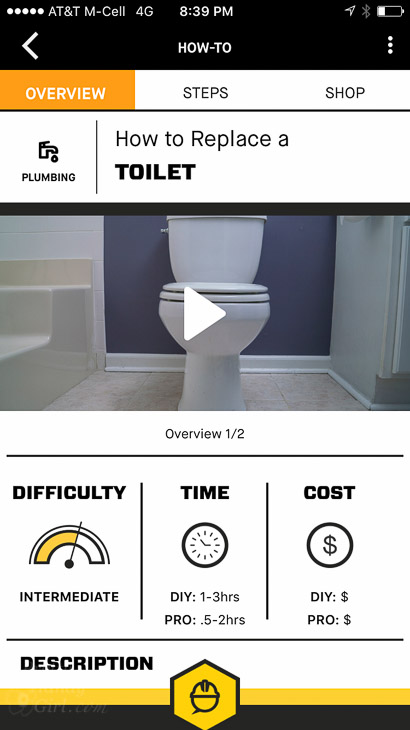

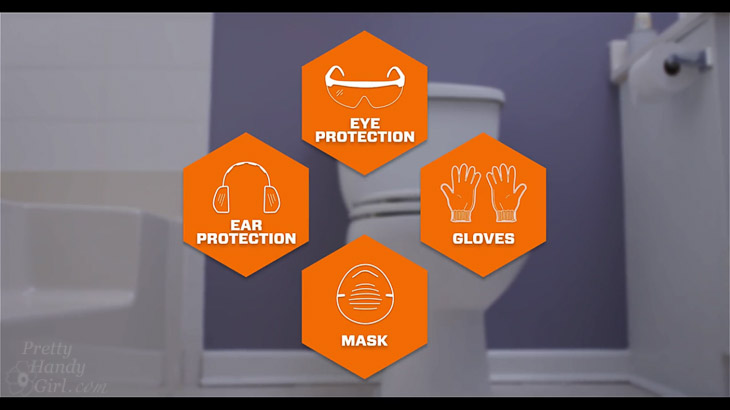

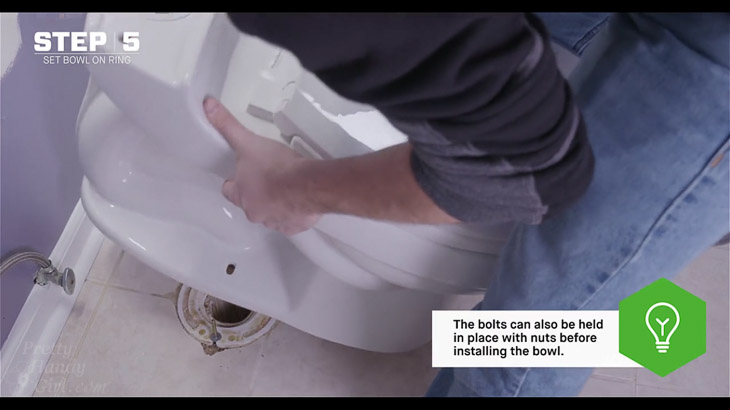

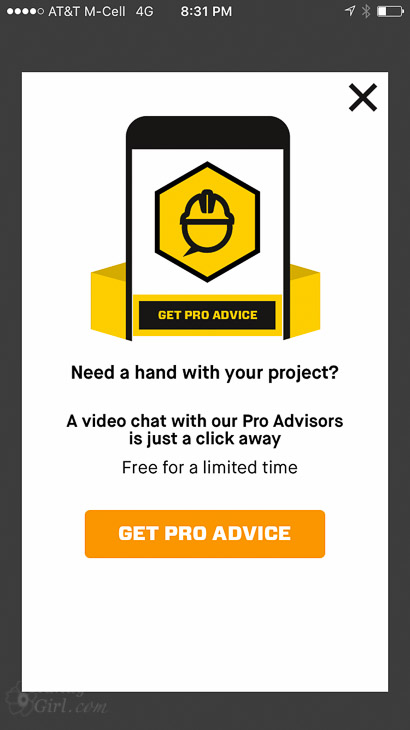

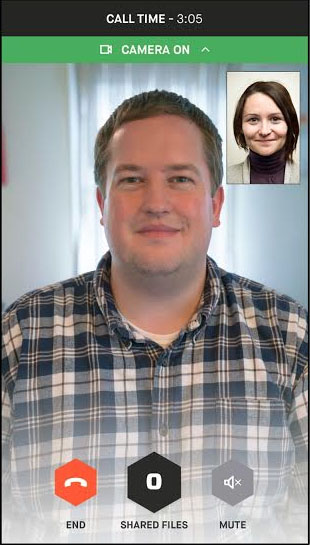

Okay, I understand you really want to update your throne. In that case, here’s How to Install a Toilet using this simple app. If you get stuck, you can press a button and have a video conference with a licensed plumber! It’s amazing how one little app can save you hundreds of dollars on plumbing repairs (and more.)

I hope you have the confidence to take on your own plumbing fix after reading these 11 Plumbing Fixes You Can Complete on your own. Remember, I believe in you, go ahead and believe in yourself.

Perfect Shower Head for a Small Shower

Perfect Shower Head for a Small Shower